Alto making plastic face shields to protect N95s

Published 10:39 am Wednesday, April 22, 2020

|

Getting your Trinity Audio player ready...

|

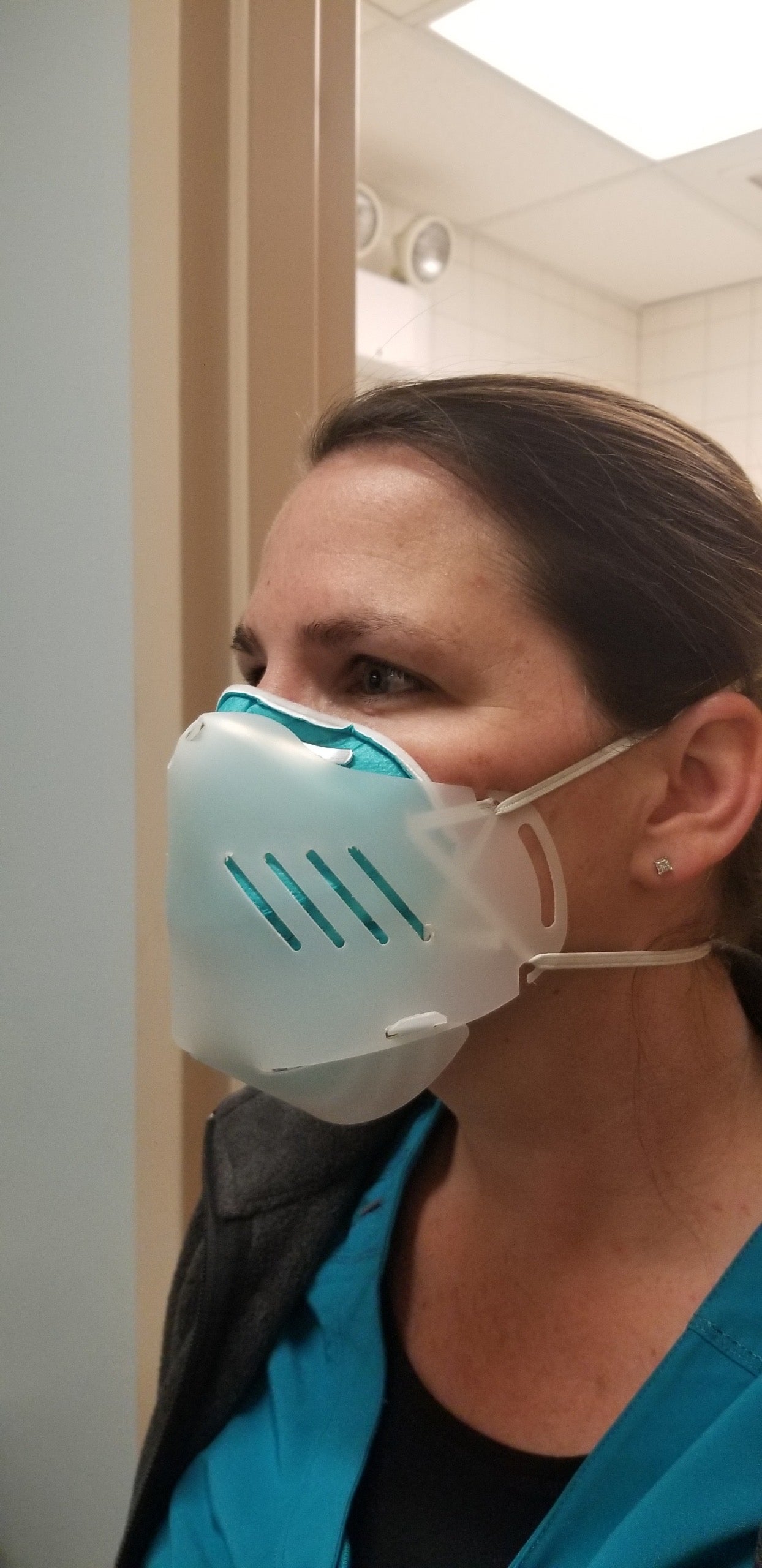

An Alto Products Corp. machinist slides a long piece of plastic through a press and then stamps out a much-needed piece of equipment.

From the press comes a plastic face shield that fits over N95 masks for healthcare workers.

The masks are used to shield the healthcare worker from any kind of fluid splatter, Alto’s David Landa said.

The masks are used to shield the healthcare worker from any kind of fluid splatter, Alto’s David Landa said.

“The sheild fits over the N95 mask,” Landa said. “Atmore doesn’t have such a problem, but we’re making 1,200 right now for Sacred Heart. It goes over N95 maks, but it fits over the mask and if that mask should get any kind of blood or fluid, or spatter, they have to throw it away.

“The shields are plastic and washable,” he said. “You can use the mask several times over. They’re making the doctors keep these masks.”

Landa said Alto is using an automated stamping press, and the company is kicking out close to 1,000 a day.

“The problem now we’re having is getting materals in in a timely manner,” he said. “In the future, we hope there will not be a need for these masks. We’re tyring to get the word out to hospitals anywhere about these masks. We’re donting all of them anyway.”

Landa said his company, which usually stamps out clutch plates, cast all the dies to be able to stamp our the plastic masks.

“We built all of the dies and molds in house,” he said. “Usually these take a long time. We’ve had some inquiries from other folks to make these and we’re sharing these with others to make them.”

Landa said the design of the mask wasn’t Alto’s. The University of West Florida and GE started making these masks via 3D printers.

“Through communication throughout the commuinty we found out about it and we knew we can stamp these thigns and ramp up production,” he said.

Additionally, Alto has eight sewing machines set up on the floor and is making resusable heavy cotton masks 24 hours a day, Landa said.

“We have bulk rolls of material coming in (this) week that we can make into disposable hospital gowns,” he said. “We have gone to several local restaurants and have placed orders for 150 meals twice a week to feed the folks at the Atmore hospital.”